In regards to manufacturing, CNC Milling Parts are actually an essential element of market. CNC devices are actually utilized in different business for instance aerospace, automobile, health and wellness, and also a lot more.

Starway CNC Milling Parts is committed to serving the customized needs of all walks of life, with high quality level to meet the various customized needs of customers

More detailed data below

|

Manufacturing Process: |

|

| Design | Create a 3D model of the part using computer-aided design (CAD) software. |

| Programming | Convert the CAD model into code (G-code) that the CNC machine can interpret. |

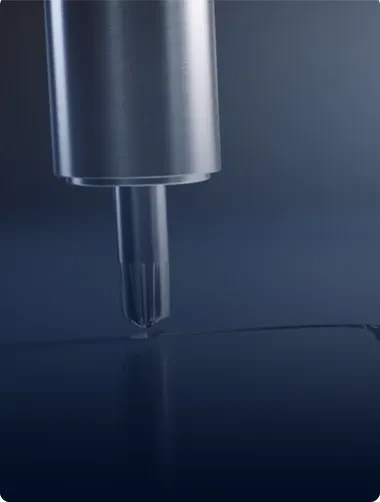

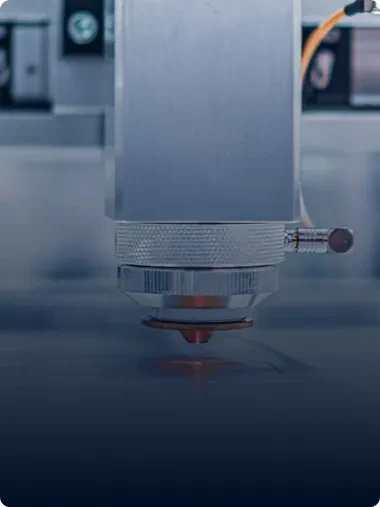

| Machining | The CNC machine follows the programmed instructions to cut, drill, and carve the metal material to produce the final part. |

| Common Materials: | CNC metal parts can be made from various plastics such as Steel,Aluminum Alloy,Copper,Brass,Plastic,Cast iron |

| Selection Criteria | Choose materials based on the part's application, mechanical performance requirements, chemical resistance, and temperature tolerance. |

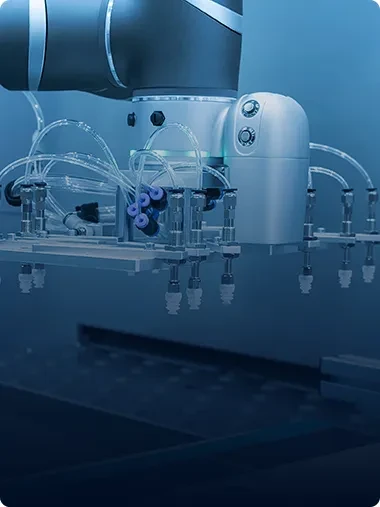

| Advantages: | Three factories provide one-stop customized services\ |

| High Precision: | Achieves high dimensional accuracy and surface finish. |

| Complex Shapes: | Capable of producing intricate geometries and detailed features. |

| Consistency: | Suitable for batch production, ensuring uniformity of each part. |

| Minimal Waste: | Reduces material waste through precise cutting. |

| Applications: | Aerospace, automotive, medical, mechanical parts |

| Industrial: | Used for mechanical components, tools, and equipment parts. |

| Automotive: | Produces interior parts, functional components, and more. |

| Medical: | Creates parts for medical devices, instrument housings, and other equipment |

| Electronics: | Manufactures housings and internal components for electronic products. |

| Consumer Goods: | Includes plastic parts for appliances, sports equipment, and other products. |

| Material Choice: | Ensure the selected metal material meets the application requirements, such as strength, temperature resistance, and chemical resistance. |

| Machining Parameters: | Adjust cutting speed, feed rate, and other parameters based on the metal's properties. |

| Post-Processing: | Parts may require additional finishing processes such as deburring, sanding, or coating to improve surface quality and functionality. |

Product Customization

Starway factory supports custom CNC Milling Parts for colors and sizes as well as materials for products. We have a wide range of CNC machines to support the choice of one-stop customized services. In addition, we also support 3D,CAD, drawings and other methods, can be customized according to the information you provide.

starway Factory production advantage

High Purity Steel Material

Tougher and more resistant to falls

High precision

The error can be controlled within ±0.05

High Efficiency and productivity

Samples will be available in about 5 days

High Flexibility and adaptability

High requirements of different products can be achieved through CNC programming

starway factory strength

Our free service hotline:+8615821850866

13

years

We have been working in the industry since 2011

32

certificates

We have obtained most of the professional certificates in the industry and insist on international standards of production.

18

awards

We have won a lot of awards for strong creativity

If you are interested in our products or you wanna make and customize products, please feel free to contact us.

Hot Tags: CNC milling parts, China CNC milling parts manufacturers, suppliers, factory, Sheet Metal Aluminum, Turned Steel, plate fabrication, Metal Parts Fabrication, laser cutting fabrication, steel fabrication factory