1. Understanding Sheet Metal Fabrication

Sheet metal fabrication is a process that transforms flat metal sheets into functional components through cutting, bending, welding, and assembly.

It plays a vital role in industries such as electronics, automotive, construction, and industrial equipment, where precision, durability, and cost-efficiency are key.

cutting, bending, welding, and stamping

2. Design and Engineering Analysis

Every successful project begins with a strong design foundation.

At Starway, our engineers review customer drawings (DWG, STEP, PDF) and evaluate tolerances, material thickness, and bending feasibility.

We often provide DFM (Design for Manufacturability) feedback to help optimize structures for production and reduce unnecessary costs.

Key Considerations

Key Considerations-

Material Selection

The choice of material (e.g., aluminum, stainless steel, cold-rolled steel) affects cost, strength, weight, and finish.

-

Bend Allowance and Deduction

This is crucial! Sheet metal stretches when bent. CAD software uses these calculations to ensure the flat pattern will bend accurately to the desired dimensions.

-

Design for Manufacturability (DFM)

A good design not only looks good on screen but is also efficient and cost-effective to produce. Engineers may suggest slight modifications to reduce complexity, minimize waste, or strengthen the part.

-

Clear Tolerance Specification

Defining critical vs. non-critical dimensions directly impacts cost and feasibility. Applying overly tight tolerances where they are not functionally required can exponentially increase manufacturing time and cost without adding value.

3. Laser Cutting and Punching - Precision Starts Here

Once the design is approved, the fabrication begins with laser cutting or CNC punching, depending on the part's geometry and material type.

Laser cutting provides high precision (±0.1mm) and smooth edges, ideal for stainless steel, aluminum, and carbon steel sheets.

paramenters of CRA series

| Cutting Method | Accuracy

|

Edge Quality | Speed | Suitable Materials | cost level |

|

|

|||||

| Laser Cutting

|

±0.1mm | Excellent | Medium | Steel, Aluminum | Medium |

| Plasma Cutting | ±0.5mm | Moderate | Fast | Thick Steel | Low |

| Waterjet Cutting | ±0.05mm | Excellent | Slow | Any material | High |

4. Bending and Forming - Shaping the Structure

Bending and forming are essential stages in sheet metal fabrication, transforming flat metal sheets into functional 3D structures such as brackets, enclosures, and panels.

At Starway, precision is achieved using advanced CNC press brakes equipped with multi-axis control, which ensures accurate angles, consistent dimensions, and smooth bending lines.

Our engineers carefully calculate the bending allowance and radius based on the material type and thickness to prevent deformation or cracking.

Whether the design requires simple right-angle folds or complex curved geometries, Starway delivers high repeatability and structural integrity, ensuring every part fits perfectly in assembly.

Compare Properties

Basic feature

|

Material |

Recommended Min. Bend Radius (× Thickness) |

Formability |

Notes |

| Aluminum 5052

|

1.0 × t

|

Excellent | Ideal for enclosures and covers |

| Stainless Steel 304

|

1.5 × t | Moderate | Requires precise control to avoid cracking |

| Cold Rolled Steel (CRS)

|

1.0 × t | Good | Common for brackets and frames |

| Brass | 0.8 × t | Excellent | Smooth surface and decorative finish |

| Copper | 1.0 × t | Excellent | Ductile, suitable for electrical parts |

5. Welding and Assembly - Building Strength

Shanghai Starway Engineering & Manufacturing Co.,Ltd.

At Starway, we use TIG, MIG, and spot welding depending on material type and appearance requirements.

MIG, TIG, and spot welding are used to fuse metal parts permanently.

Riveting

A mechanical fastening method ideal for joining dissimilar metals or where heat from welding is a concern.

Threaded Fasteners

Using nuts, bolts, and screws for assemblies that may need disassembly for maintenance.

6. Surface Finishing - Function Meets Aesthetics

The Final Touch

Surface finishing enhances the part's appearance, durability, and functionality.

Powder Coating

A dry powder is electrostatically applied and then cured under heat. It creates a durable, corrosion-resistant, and attractive finish in a wide range of colors.

Anodizing

(For Aluminum) An electrochemical process that increases corrosion resistance and surface hardness. It can also add color.

Brushing

Creates a textured, directional grain pattern for a sleek, matte look.

Passivation

(For Stainless Steel) A chemical process that removes free iron from the surface, enhancing corrosion resistance.

7. Quality Inspection and Final Delivery

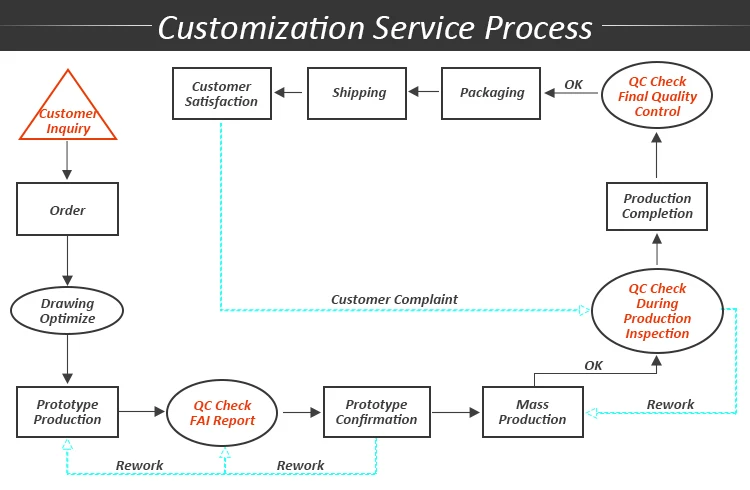

starway customized service

Before shipment, every part undergoes strict dimensional and surface inspection using CMM, calipers, and visual checks.

01

Pre-sale service

Starway starts each project by understanding customer needs.

Engineers review drawings, tolerances, and materials to offer the best machining solution.

We optimize designs for cost and precision, then deliver a detailed quotation and feasibility report before production begins.

02

Production & Inspection Service

After order confirmation, Starway ensures strict process control from prototype to mass production.

Each part undergoes FAI, in-process, and final QC using CMM and surface testers - guaranteeing accuracy, consistency, and reliability.

03

After-sales & Continuous Support

Our service continues after delivery.

We provide inspection and traceability documents, while our technical team offers installation guidance and feedback support to maintain long-term reliability.

Detailed inspection reports are provided to ensure complete traceability and compliance with customer specifications.

9. Why Choose Starway for Custom Sheet Metal Fabrication

https://www.starwaymetals.com/

-

In-house laser cutting, bending, welding, and finishing

ISO 9001:2015 certified quality management

Global shipping and on-time delivery

-

Support for prototype, small batch, and volume production

-

Fast turnaround with full technical support

Global shipping and on-time delivery

Conclusion

One-stop solution Factory in China

The journey of a custom sheet metal part is a testament to modern manufacturing's precision and efficiency. By understanding this process-from digital design and precise cutting to skilled forming and protective finishing-you can make more informed decisions for your next project and appreciate the engineering marvel in everyday products.

From design to delivery, custom sheet metal fabrication is a process of precision, collaboration, and control.

At Starway, we integrate advanced technology with decades of manufacturing experience to help clients bring high-quality metal products to life - efficiently and reliably.

8615251708787

Billy.feng@starwaymfg.com