Here are seven key benefits of working with a professional custom CNC machining partner Starway MFG, to elevate your product design process.

1. Exceptional Precision and Repeatability

One of the biggest advantages of custom CNC machining is its unmatched accuracy. Computer-controlled machining ensures that every cut, angle, and dimension aligns perfectly with your design specifications.

At Starway, our advanced 3-, 4-, and 5-axis CNC machines deliver consistent tolerances within microns, ensuring that every component-no matter the batch size-meets exact standards of performance.

Our factory & quipment

2. Design Flexibility for Complex Geometries

Unlike standard parts production, custom CNC machining supports highly complex and innovative shapes. Designers can experiment with intricate surfaces, deep cavities, or curved features without compromising quality.

Whether you're developing aluminum enclosures or precision plastic housings, our engineering team can help optimize your CAD models for the best manufacturability and function.

Multi-axis machining enables production of undercuts, curves, and intricate internal channels.

Compatible with hybrid manufacturing processes (e.g., CNC + 3D printing).

Supports both 2D and 3D CAD/CAM data integration for efficient design-to-production workflow.

3. Rapid Prototyping and Faster Time-to-Market

Speed matters in modern product development. A custom CNC machining service allows you to move from design to prototype in a matter of days, not weeks.

This agility helps you validate your design faster, make quick iterations, and reduce costly production delays. Starway's in-house prototyping line ensures rapid turnaround while maintaining tight quality control.

CNC machining allows same-day prototype delivery for critical design validation.

Simplifies design iteration-engineers can make adjustments and reprocess immediately.

Reduces tooling setup time compared with traditional molding or casting.

4. Cost-Effective for Small and Medium Batches

Many companies assume "custom" means "expensive." In reality, CNC machining can be highly economical for small-batch or on-demand production.

You save costs on tooling, setup, and inventory storage, while producing only what's needed. Starway offers flexible production runs to support early-stage projects and mid-volume manufacturing.

Eliminates the need for expensive molds and long lead times.

Material waste is minimized through optimized tool paths.

Ideal for pilot production runs or market testing.

5. Broad Material Compatibility

CNC machining supports a wide variety of materials-from metals like aluminum, brass, and stainless steel to engineering plastics such as PEEK, nylon, and acetal.

This gives you more freedom to test different materials for your prototype or end-use parts without needing to switch production processes.

Once the prototype is verified, the same CNC program can be scaled for mass production.

Ensures dimensional consistency across different production volumes.

Compatible with automated tool changers and robotic loading systems.

Precision CNC Machining Materials Comparison

|

Material |

Density(g/cm³) | Tensile Strength(MPa) | Machinability | Key Advantages | Typical Applications |

| Aluminum 6061 | 2.7 | 310 | Excellent | Lightweight, corrosion resistant | Prototypes, housings, brackets |

| Stainless Steel 304 | 8.0 | 520 | Good | High strength, corrosion resistance, good formability | Medical, food, structural parts |

| Brass C360 | 8.5 |

|

Excellent | Easy to machine, smooth finish | Connectors, fittings, decorative parts |

| Copper | 8.9 | 210 | Fair | Excellent electrical & thermal conductivity | Electrical parts, heat exchangers |

| Titanium | 4.4 | 900 | Moderate | High strength-to-weight ratio, biocompatible | Aerospace, medical, performance parts |

| Nylon (PA6) | 1.15 | 80 | Good | ough, wear resistant | Gears, bushings, mechanical parts |

| PEEK | 1.32 | 97 | Fair | High-temperature, chemical resistant | Aerospace, medical, chemical equipment |

| Acrylic (PMMA) | 1.18 | 65 | Good | Excellent transparency, smooth surface | Display parts, lenses, prototypes |

Precision CNC Machining Materials

CNC-Machining-Aluminum

CNC-Machining-Brass

CNC-Machining-Brass

CNC-Machining-Copper

CNC-Machining-Titanium

CNC-Machining-Stainless-Steel

CNC-Machining-Stainless-Steel

CNC-Machining-Nylon

CNC-Machining-Nylon

CNC-Machining-PEEK

CNC-Machining-PEEK

CNC-Machining-Acrylic-PMMA

6. Seamless Scalability from Prototype to Production

Once your prototype is validated, you can easily scale the same CNC process into full production. Because the machining programs are digital, it's simple to replicate precision across hundreds or thousands of units.

Starway's facilities in Nantong and Jingdezhen are equipped for both rapid prototyping and mass production, ensuring consistent quality at every stage.

7. Guaranteed Quality and Reliability

Every custom CNC project at Starway undergoes rigorous quality checks using advanced inspection tools such as CMM, projectors, and surface testers.

Our ISO-certified system ensures that every part leaving our facility meets global quality standards-helping you reduce rework, minimize risk, and strengthen your product reputation.

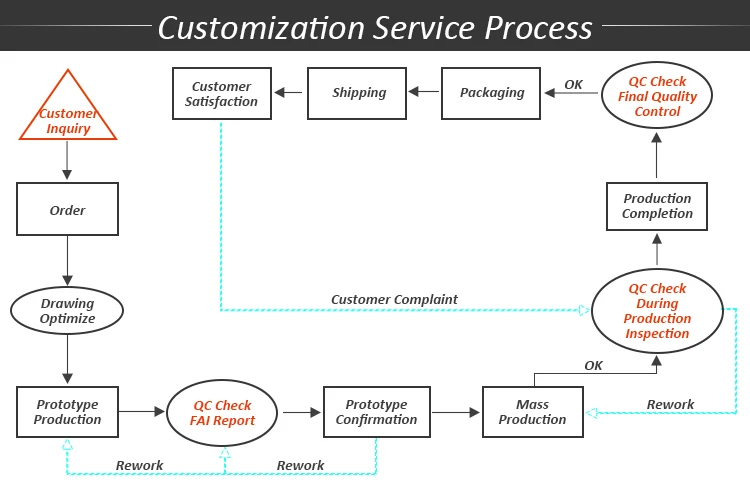

customization Service process

01

Pre-sale service

Starway starts each project by understanding customer needs.

Engineers review drawings, tolerances, and materials to offer the best machining solution.

We optimize designs for cost and precision, then deliver a detailed quotation and feasibility report before production begins.

02

Production & Inspection Service

After order confirmation, Starway ensures strict process control from prototype to mass production.

Each part undergoes FAI, in-process, and final QC using CMM and surface testers - guaranteeing accuracy, consistency, and reliability.

03

After-sales & Continuous Support

Our service continues after delivery.

We provide inspection and traceability documents, while our technical team offers installation guidance and feedback support to maintain long-term reliability.

Starway Precision CNC Machining Services

Advantages of Precision CNC Parts

High Dimensional Accuracy

Precision CNC parts are manufactured with extremely tight tolerances-often within ±0.005 mm. This level of accuracy ensures that each part perfectly matches the 3D model design, making them ideal for assemblies requiring precise fit and function.

Short Lead Time and Cost Efficiency

CNC machining provides a direct path from digital design to finished part, minimizing setup time and tooling costs. This makes it a cost-effective solution for both rapid prototyping and low-to-medium production runs.

Wide Material Compatibility

Precision CNC machining supports metals such as aluminum, stainless steel, brass, and titanium, as well as engineering plastics like PEEK, nylon, and acrylic. This flexibility allows engineers to select materials based on performance, weight, and cost requirements.

Superior Surface Finish

ICNC machining delivers smooth surface finishes directly from the cutting tool, often eliminating the need for secondary polishing. This results in better sealing performance, lower friction, and an overall refined appearance for your final product.

Conclusion

Choosing a custom CNC machining service gives your design process the precision, flexibility, and control it deserves. From one-off prototypes to full-scale production, CNC machining bridges the gap between creativity and manufacturability.

At Starway MFG, we're committed to delivering reliable, high-quality CNC parts that empower your next product to perform flawlessly.

Ready to bring your design to life?

Get a Quote

Contact our team today to discuss your custom CNC machining project.

Our address

Shanghai Starway Engineering & Manufacturing Co., Ltd.

Phone Number

8615251708787

Billy.feng@starwaymfg.com